Tracking the continuously changing market requirements, Symetal has managed to retain a flexible and highly adaptive profile thanks to its light structure, modern equipment and deep technical know-how.

Focusing on top quality, advanced technology and customized service we target at meeting customer’s requirements.

To this end, we also capitalize on the metallurgical knowledge of our parent company ElvalHalcor, analyse the technical needs of our customers, and finally propose and supply tailor-made solutions which meet their specifications.

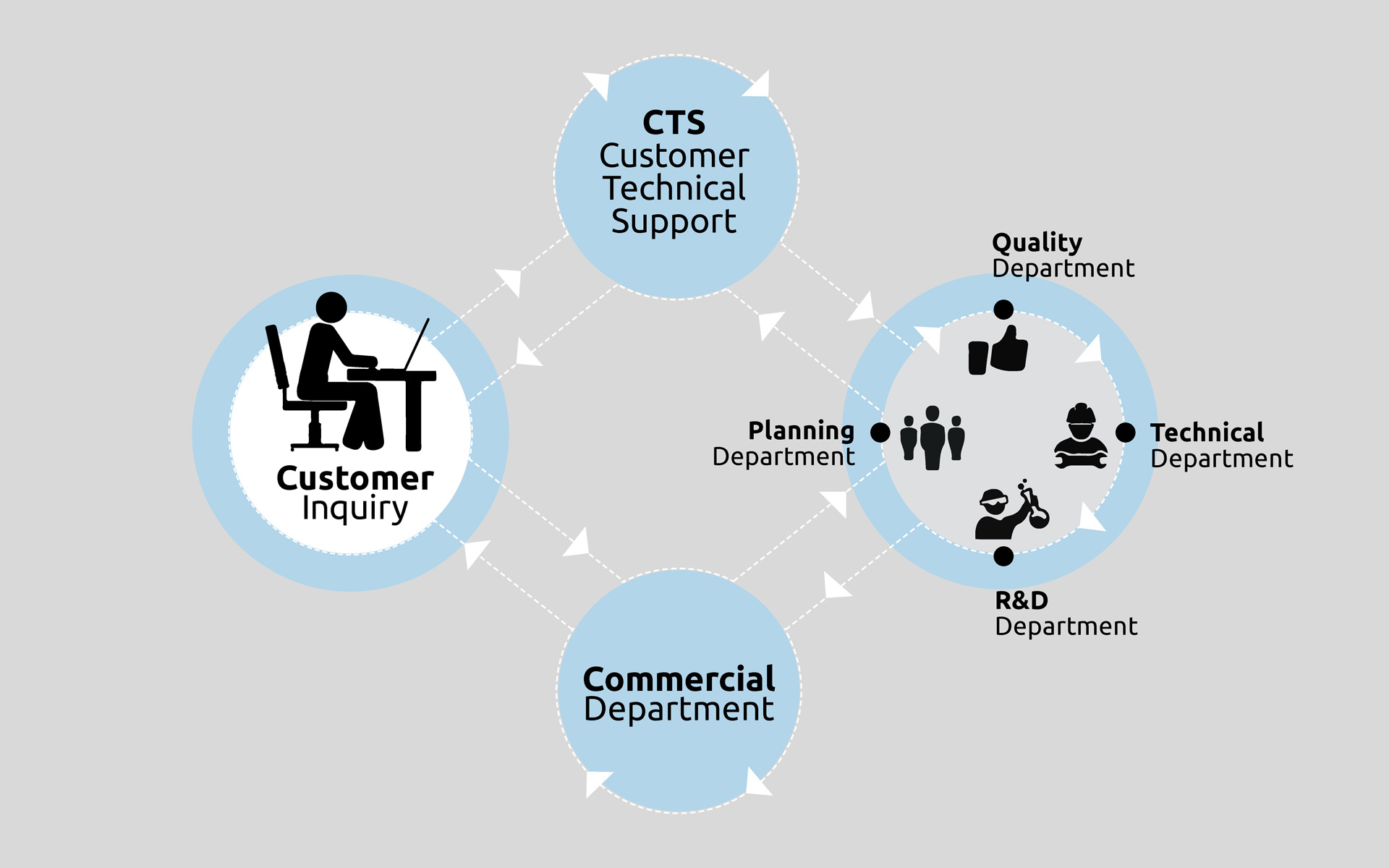

Our successful way of doing business is based on the continuous cooperation of the three following teams: